Niigata ICC Pallet System and Multi-Level Stacker

Why Automate your machining operations with Niigata?

- Flexible Automation = Higher productivity

- Flexible Automation = Assists with business demand fluctuations

- Flexible Automation = Reduces production lost time (repetitive work) such as setups, manual transfer

- Flexible Automation = Reduces monies held in WIP & Inventories

- Benefits are increased revenue & profit, increased through put, and resource efficiency.

Niigata ICC (Intelligent Cell Controller)

Machining Program per pallet

- Simple set-up & easy program changes while in machine run mode.

- Scheduled cell production operations are controlled by the pallet carrier.

- NC program, systematic operation corresponding to tool condition, and un-manned operation.

Easy to change data by operator

- Improved productivity corresponding to work conditions.

Shut-down funtion when production schedule is completed.

- Energy-saving.

4 Face Control

Four face control of individual part types. 0°/90°/180°/270°assigned NC programs which are set for each face and then automatically run in the cell. Since table rotation is executed in the 4 face control function, B-axis rotation instruction in each NC program is not required. The same NC program can be applied to different faces. 4 or 8 faces are available on the ICC system as a Factory default setting.

ICC Screens and Operations

Steps to initiate system operations

- Create pallet schedule assignment.

- Register NC programs to ICC.

- Set production schedule.

- Press Cycle Start button.

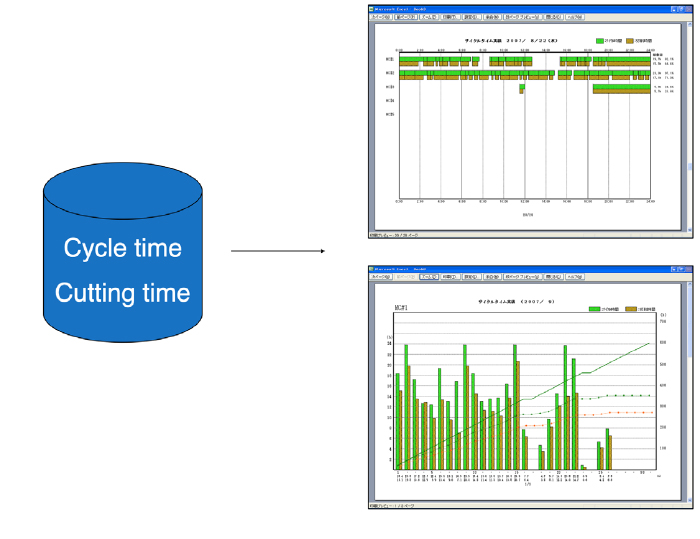

Graphic Display of Production Results

This optional software provides daily/monthly production results in graphical display. Note: This software is a stand-alone type.