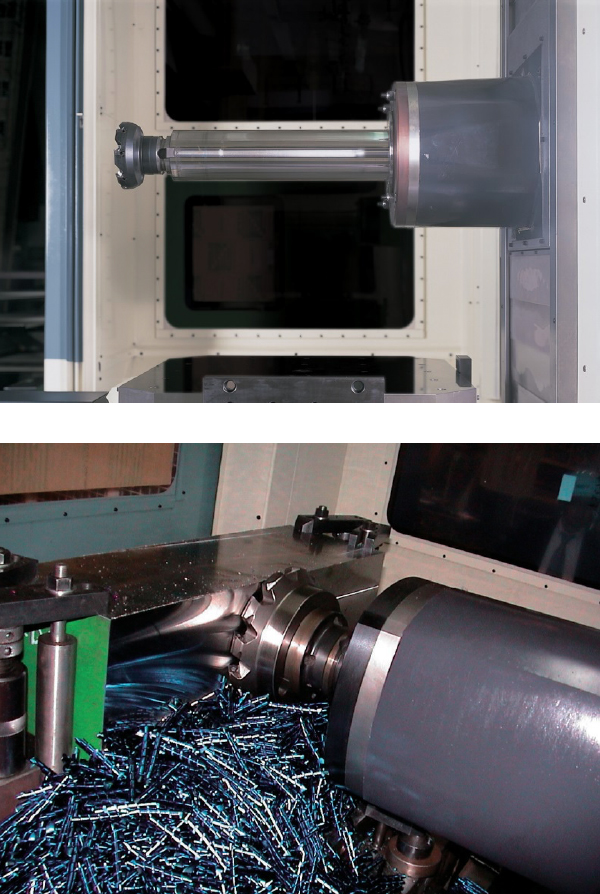

HN80E-BAR Heavy Duty Boxway Horizontal Machining Center (HMC)

- The HN80E-BAR brings long-sought improvements in performance and accuracy to the work traditionally done by horizontal boring mills.

- BAR style spindle with spindle core cooling system.

- Heavy duty boxway machining center with V-shaped guideways, hardened and ground.

- Precision straightness of motion, elimination of roll, pitch and yaw.

- Hand scraped squareness and perpendicularity for increased volumetric accuracy.

- Rapid speed of 50m/min (1968 ipm).

- Solid meehanite cast iron machine frame.

- Outstanding stability, dampening through extensive ribbing of machine frame.

- Gear driven spindles that generate extremely high torque.

- Niigata’s mean workzone is the most generous in the industry.

| SPECIFICATIONS | ITEM | HN80E-BAR | |

|---|---|---|---|

| TRAVEL & WORK CAPACITY | X axis travel (longitudinal table) | 1530 mm | 60.2" |

| Y axis travel (vertical head) | 1230 mm | 43.3" | |

| Z axis travel (column in & out) | 1020 mm [1200 mm] | 40.2" [47.24"] | |

| Max Work / Swing Diameter | 1750 mm | 68.9" | |

| Max Work / Height | 1400 mm | 55.1" | |

| TABLE | Table working surface | 800 x 800 mm | 31.5 x 31.5" |

| Table increments [option] | 1° [0.001°] | 1° [0.001°] | |

| Maximum mass on pallet | 2500 kg | 5500 lbs | |

| SPINDLE | Spindle speeds | 6000 min-1 | 6000 rpm |

| Spindle speeds (OP) | 15000 min-1 | 15000 rpm | |

| Spindle taper | CAT 50 BIG PLUS HSK100A option |

CAT 50 BIG PLUS HSK100A option |

|

| FEEDRATE | Rapid traverse X axis | 50 m/min | 1968 ipm |

| Rapid traverse Y axis | 50 m/min | 1968 ipm | |

| Rapid traverse Z axis | 50 m/min | 1968 ipm | |

| AUTOMATIC TOOL CHANGER (ATC) | Tool magazine capacity | Chain 62 [88/128/175/255] Matrix [126/178/230/308] |

Chain 62 [88/128/175/255] Matrix [126/178/230/308] |

| GENERAL | Machine weight approx. | 32000 kg | 70000 lbs |

| Control | Fanuc 30iB (31iB) | Fanuc 30iB (31iB) | |

All specifications subject to change without notice.

Superior Features, Higher Productivity Over Traditional Boring Mills

- BAR/QUILL W axis travel 21.1"

- Center mounted spindle. Eliminates column twist.

- Z-axis column feed. Superior accuracy & rigidity vs. table-fed machines.

- Full enclosures faster traverse, faster feed & speed vs. horizontal boring mills.

- True coolant thru spindle.

- ATC, APC, to maximize performance & productivity.

- Rigid snout, Heavy duty high torque spindle. 3500rpm 37kW (40HP), 1836N•m (1,354ft•lbs.) - Standard, 3500rpm 30kW (60HP), 1318N•m (972ft•lbs.) - Optional,

- BAR head with core cooling - Optional