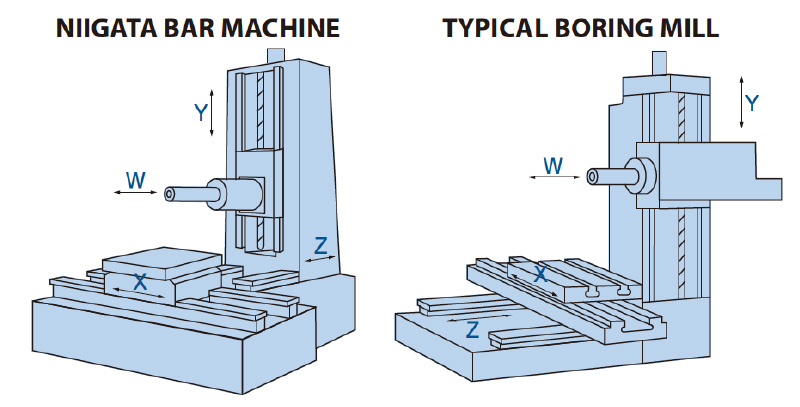

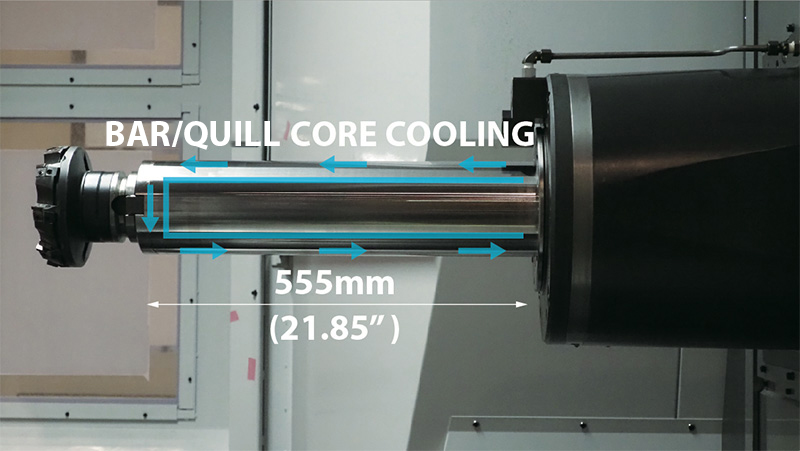

- Rigid/Head Stock Design The BAR versions bring long-sought after improvements in performance and accuracy to the work traditionally done by horizontal boring mills.

HN-S Bar Series

Superior Features Over the Traditional Boring Mills

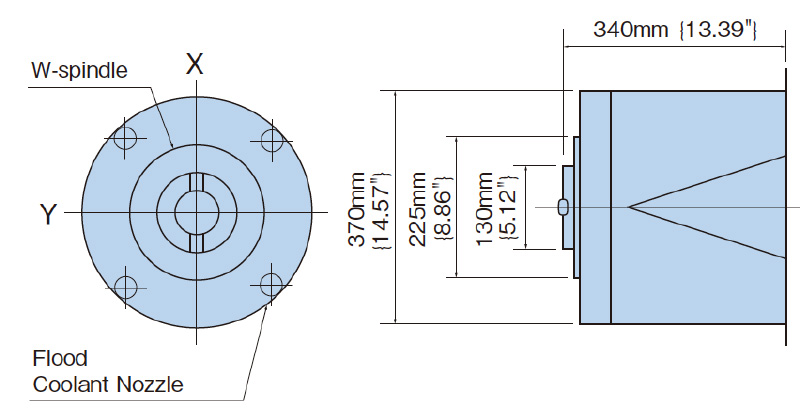

- Rigid Spindle Snout Reduces the need to extend the quill to reach the part; provides a high radial load capability for heavy milling cuts.

- Center-Mounted Spindle Eliminates the column twist of side-mounted spindle.

- Column Feed Superior accuracy and rigidity vs. table-fed machines, with compound slides (stacked X and Z axes).

- Faster Traverse and Feed Speeds Higher productivity, more parts per shift, faster ROI vs. horizontal boring mills.

- Ergonomically Superior A full enclosure is standard, along with automatic tool changer and pallet changer to maximize the performance and productivity of your operation.

- True Coolant Thru the Spindle Better cutting conditions, longer tool life, superior chip removal, not available from some competitors, and special tool holders are not required.

Bar/Quill Capability on Horizontal Machining Center

Niigata’s model: HN-S Series machining centers, always known for rugged, high speed, reliable performance, can be equipped with a Bar/Quill style spindle. The BAR versions bring long-sought improvements in performance and accuracy to the work traditionally done by horizontal boring mills.